Major Works

Two Shell Plaza

Houston, Texas, 1972, 341ft, Reinforced Concrete

Social and Economic Context

|

| Fig. 1:Shell Plaza with One Shell Plaza on the left and Two Shell Plaza on the right |

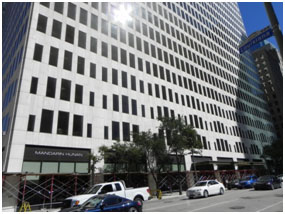

Shell Plaza, consisting of One Shell Plaza and Two Shell Plaza, was built in the midst of Houston’s construction boom in 1971 in the center of a vibrant downtown for the headquarters of Shell Oil Company (Figure 1). One Shell Plaza was designed for office space and Two Shell Plaza (Figure 2) as a flexible space initially for parking with the potential to be converted into office space as needed. Designed by the innovative team of architect Bruce Graham and structural engineer Fazlur Khan and sponsored by the real estate company Hines Incorporated, Two Shell Plaza (also known as the Walker Building) was a successful experiment in tall concrete building design in Houston that has inspired and informed an urban concrete expansion.

|

| Fig. 2: Two Shell Plaza close up of the front view |

The discovery of Texan oil in 1901 revolutionized the city of Houston. With the development of over 3,600 oil companies, the city emerged as a urban energy centre. Urban growth was stimulated by federal funds post World War II and quotas on oil imports in the 1960s that drove up domestic prices. Rapid construction brought new office space for the emerging business, more than doubling the number of Houston’s commercial buildings.1

Houston is the only city in the United States without a zoning ordinance. Its urban growth was driven not by government policies and money, but by the private sector leadership of oil and financial companies. Their limited influence coupled with low property taxes enabled urban sprawl and made Houston a favorable location for real estate companies like Hines.2 Today Houston is the fourth largest city in America.3 Hines real estate continues to fund and manage innovative concrete construction projects in Houston and across the country.4 The construction of Two Shell at the peak of Houston expansion provided high density space for a growing city and economy without adding to urban sprawl.

Forces and Form

Khan was a master of structural engineering innovation and Two Shell Plaza is a prime example of his innovation at work. For Khan, innovation was an iterative process that took place over several building designs. Two Shell Plaza is a part of this exploration, which evolved from the designs of the Dewitt-Chestnut Apartments, the Brunswick Building and the Marine Midland Bank.5

|

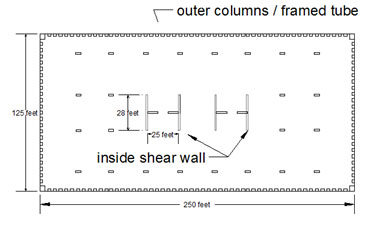

| Fig. 3: Floor plan of Two Shell Plaza showing columns and shear walls in a "tube in a tube" system |

The Dewitt-Chestnut Apartments in Chicago is a “framed tube” meaning that closely spaced columns on the building perimeter, combined with the beams connected to it acted as a rigid frame, like a wall with holes punched though it for windows. The tube acts similar to a cantilever beam projecting out of the ground and resists lateral (wind) forces. The design of the Brunswick building has a “tube-in-tube” system where the second tube is formed by the interior “shear walls”, which are the concrete walls surrounding the building core. Figure 3 shows a floor plan of Two Shell showing the columns and interior shear walls.

|

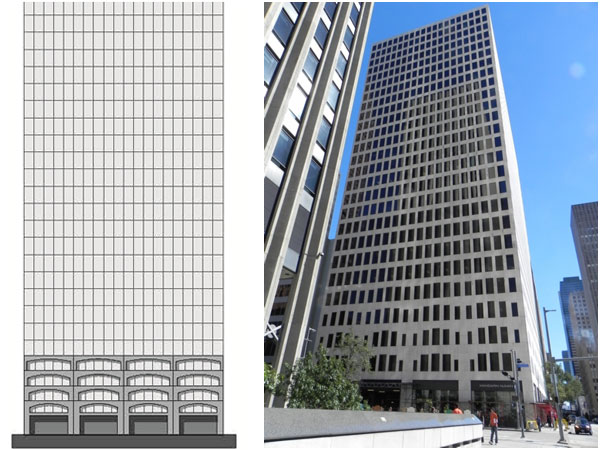

| Fig. 4: Column transfer through haunched beam action (photo by Maria Garlock, sketch by Razvan I. GhilicMicu based on a sketch by David Fung) |

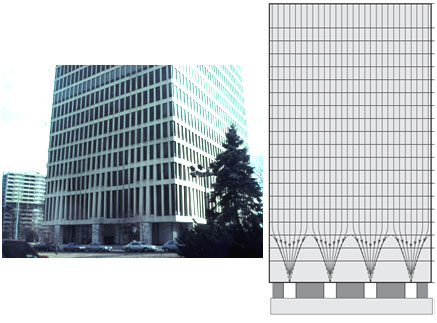

Two Shell Plaza utilizes the same tube-in-tube concept as the Brunswick Building, but develops a more efficient and refined solution for transferring the loads from the closely spaced columns above to the widely spaced columns below.This transfer is done through a series of haunched beams as shown in Figure 4. Thehaunched beamsgradually direct forces towards the columns that continue to the ground level. The Marine Midland Bank is a similar alternative of this gravity force transfer, where the depth of the columns as well as the width of the columns are varied at the lower levels creating an arch-like action and an undulating facade.6 (See Figure 5)

|

| Fig. 5: Marine Midland Bank in Rochester, NY, uses “arch-like” action to transfer column loads at the ground level (photo by J. Wayman Williams Jr., sketch by Razvan I. GhilicMicu) |

Conclusion

Graham and Khan’s design of Two Shell Plaza was driven by the pursuit of an efficient structural method of transferring gravity loads, and their solution ebodiedstructural expression. According to Khan, structural logic and architectural expression are irrevocably linked.7 Khan wrote that architectural goals “makes the engineer more conscious of the need to design the structure as efficiently, elegantly, and articulately as possible”.8

The design remains true to Khan’s goal of efficiency and only incorporates structural systems to resist loads without extraneous elements. The building’s aesthetics is thus derived not from added architectural elements, but from the expressed structure. Khan believed that simplicity is a function of beauty derived from harmony and logic.9 The aesthetics of Two Shell Plaza draws from the structural logic of the exposed facade that answers an engineering challenge with a simplicity that can be read and understood by the public eye.

1. Fischer, R. (1989). ‘Urban policy in Houston, TX’, Urban Studies, 26, pp. 144-154.

2. Ibid.

3. Houston History 2010, Historic Houston, Available From:

4. Hines Representative (2010). Discussion of Hines, Inc. and Shell Plaza Construction and Maintenance, at Two Shell Plaza Houston, TX.

5. Ali, M.M. (2001). Art of the Skyscraper: The Genius of Fazlur Khan, Rizzoli: New York.

6. Ibid.

7. Bonowitz, D 1985, Load distribution to base columns of concrete tubes and bearing walls: Four approaches by Fazlur Khan, Senior thesis, Princeton University, Princeton.

8. Khan, F. cited in Bonowitz, D 1985, Load distribution to base columns of concrete tubes and bearing walls: Four approaches by Fazlur Khan, Senior thesis, Princeton University, Princeton.

9. Khan, Y. cited in Saliklis, EP, Bauer, M, &Billington, DP 2008, ‘Simplicity, scale, and surprise: Evaluating structural form’, Journal of Architectural Engineering, vol. 14, no. 1, pp. 25-29.