Major Works

One Shell Plaza

Houston, Texas, 1971, 714ft, Reinforced Concrete

Social and Economic Context

|

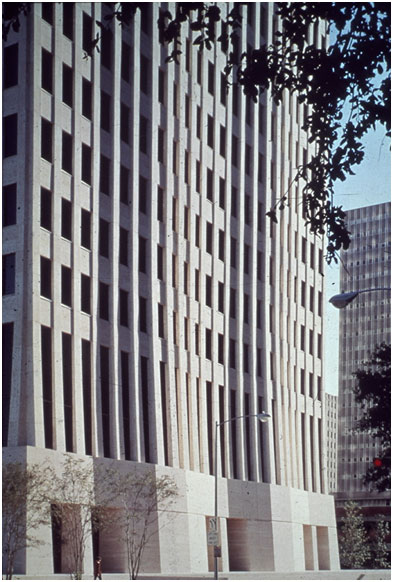

| Fig. 1: One Shell Plaza (photo by J. Wayman Williams Jr.) |

One Shell Plaza (Fig. 1) is a 50-story, 715-foot tall building located in Houston, Texas. Along with Two Shell Plaza across the street, it serves as the corporate headquarters for the Shell Oil Company. Architect Bruce Graham, along with Fazlur Khan, designed One Shell Plaza to be a bold yet structurally expressive building for Shell, and the pair earned much recognition for their design. At the time of its completion in 1971, One Shell Plaza was the tallest building west of the Mississippi River and the tallest reinforced concrete structure in the world. It is the first all-lightweight concrete building and one of the first tube-in-tube structures ever built.1 Finally, it was the first tall building to populate the Houston skyline, largely due to the efforts of developer Gerald D. Hines to establish Houston as “the best city in the South.”2

Unlike Chicago, where the rise of tall buildings was largely spurred by Mayor Richard Daley’s vision for the city, Houston is a city built by developers. One of Houston’s primary developers was Gerald D. Hines, founder of Gerald D. Hines Interests (now Hines). Hines belonged to a class of developers described as “investment builders,” who specialized in financing building projects, contracting out the work to architects and engineers, supervising the construction, and ultimately leasing and managing the built spaces.3 Although Hines began his career in 1957 quietly developing apartment complexes in the Houston suburbs,4 he would quickly rise to become one of the greatest influences on Houston’s urban development.5 Hines believed that Houston had the potential to become one of the best cities in the country, and he made it his goal to help his city achieve that status.

By the late 1960s, Houston had become the fastest growing city in the United States and housed the country’s sixth largest population. It boasted the world’s largest domed stadium (the Astrodome), the headquarters for NASA’s manned spacecraft program, and plans for a new international airport (now Bush Intercontinental Airport).6 Despite this increased development, however, it still did not have much of a downtown business district, so Hines focused his attention on attracting big corporations like the Shell Oil Company to the city. His strategy was simple: hire the best architects and engineers to create for each company a unique and elegantly designed building. For Shell’s new corporate headquarters at One Shell Plaza, he contacted Bruce Graham at Skidmore, Owings, and Merrill (SOM) in Chicago with the task of designing a bold yet efficient building for the space.

When Hines had contacted SOM about designing One Shell Plaza, Fazlur Khan was already working on a novel tube-in-tube structure based on past building designs. He had begun to experiment with new structural forms following the completion of the Brunswick Building in Chicago in 1965, looking for ways to make the structure even more efficient. Construction of One Shell Plaza began in 1967 and was completed in 1971. As the tallest building in Houston at the time, it stood out as a major structure in the Houston skyline, as Hines had assured Shell it would be. One of the prominent visual characteristics of One Shell Plaza is its undulating exterior columns. One Shell Plaza was Hines’s first project with a major architectural firm, and it marked for him the transition from suburban to urban development.7

Forces and Form

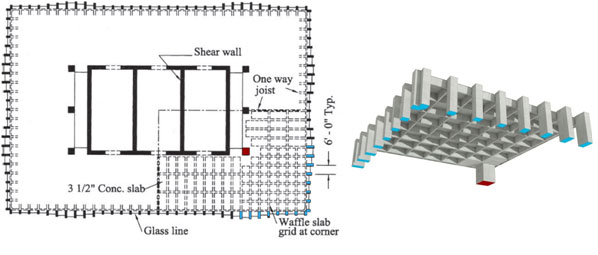

One Shell Plaza was the first instance of what Fazlur Khan called a “tube-in-tube” structure. Figure 2 shows that the inner “tube” is formed by the shear walls that make up the core of the building (housing elevators, stairwells, and mechanical equipment rooms), while the outer “tube” is formed by the exterior columns spaced every 6 feet around the perimeter of the building. The inner tube and outer tube work together to resist gravity loads and lateral loads (i.e., wind) and to provide additional rigidity to the structure to prevent significant deflections at the top. With this form, the 50-story One Shell Plaza is able to be taller and lighter than a traditionally designed framed tube building, while still maintaining the stiffness of a much shorter building.8

|

| Fig. 2: Floor plan (left) of One Shell Plaza showing varying sizes of columns on the perimeter and the shear wall at the core; and rendering of the waffle slab grid at the corner (right). |

At the time of its completion in 1971, One Shell Plaza was the tallest reinforced lightweight concrete building in the world. Because of Houston’s poor soil conditions, however, One Shell Plaza’s foundations would only be able to support a 35-story normal weight concrete building. To give the Shell Oil Company the tallest building possible, Khan decided to use lightweight concrete instead, weighing only 115 psf. This would enable Hines to build a 50-story structure with the weight of a 35-story one – approximately 40% more office space!9

|

| Fig. 3: One Shell Plaza’s exterior columns vary in depth based on gravity loading, which creates an undulating pattern visible at the street-level (photo by J. Wayman Williams). |

There was, however, one other issue with lightweight concrete that Khan needed to consider before construction could began. Lightweight concrete is highly susceptible to creep, or the shortening of a column as a result of sustained loading. If each column had the same concrete area but a different load, they would shrink over time by different amounts, which would cause problems ranging from major issues of cracking and sloped floors to minor inconveniences such as doors that do not close properly and walls that crack. To guard against this differential shrinkage, Khan developed strict quality control measures for the concrete he used and performed extensive tests in the field and in the laboratory to better understand its behavior.10 He furthermore designed the perimeter columns such that each column experiences similar stresses in the concrete over time, and therefore undergoes the same amount of shortening. Because stress is the force in the column divided by its cross-sectional area, this is normally accomplished in buildings by varying the dimensions of the perimeter columns (that is, using wider or deeper columns), then covering them with a façade to hide the structure. Graham and Khan, however, preferred to express the structure, so they instead chose to emphasize the dimension changes by varying the depth of each perimeter column based on the distribution of forces.11 This resulted in the elegant undulations that are characteristic of One Shell Plaza (Figures 1 and 3).

|

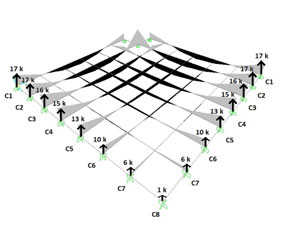

| Fig. 4: Bending moment diagram and vertical reactions for floor slab. Black regions below the graph indicate positive bending moments, while gray lines above the graph indicate negative bending moments. Vertical reactions are shown as arrows. |

To illustrate that the undulating design is driven by the distribution of gravity loads in the two-way slab, we modeled one corner of a typical floor using the structural analysis software. The model consists of a two-way slab with joists 6 feet on center in both directions. Fixed supports were placed wherever the slab intersected a column and the edges of the cross-sectional cut were left unrestrained. A point load was applied at each point of intersection, to represent the full dead load plus 25% of the live load that acts over the 6 feet x 6 feet area surrounding that node (i.e. the node’s tributary area). The term “dead load” refers to the weight of the structure itself, and “live load” refers to other loads that act on the structure and can be broken into “long term” and “short term” live load categories. The 25% live load represents the relatively permanent portion of the full live load that acts on the structure. Figure 4 shows that the bending moments and vertical reactions are proportional to the size of the columns.

Mat Foundation

Until One Shell Plaza was constructed, Houston’s poor soil conditions were an obstacle that limited the height of tall buildings designed in the business area downtown. Northern US cities such as New York or Chicago have a soil formation comprised of mostly bedrock. Conversely, Houston’s soil consists of mostly sand, silt, loam, and clay. This composition swells, shrinks, and is sensitive to variable displacements when heavy loads are applied. Tall buildings constructed directly on this soil would experience noticeable settlement. To solve this problem, the design team utilized a mat (or floating slab) foundation, one of Houston’s common solutions to this problem. Mat foundations are large concrete slabs built under the building. The mat was 8’3” thick, making it the deepest excavation attempted in Houston at the time.12

Conclusion

In addition to being structurally innovative, One Shell Plaza succeeded in being aesthetically elegant as well. The varying depths of the columns, designed to support the structure more efficiently, create gently undulating exterior walls that can be appreciated from a distance as well as close up (Fig. 3). The bold undulations apparent at the base of the structure taper off gradually along the height of the building successfully express the reduction in load from bottom to top, while still remaining aesthetically inviting. These features emphasize the structure’s height and magnificence from the street-level, and yet building looks exceptionally slender because of them. For a more open entryway, some of the exterior columns ended at the transfer girder as opposed to the ground.Approaching the building, the twelve-foot entryways created by the transfer girder make the lobby area scale well to the pedestrian. The building remains distinctive to this day.

1. Khan, Y.S. (2004).Engineering Architecture: The Vision of Fazlur R. Khan. New York: W.W. Norton & Company.

2. (1972). One Shell Plaza: The tallest building west of the Mississippi. Architectural Digest, 1, 21-22.

3. Bloom, J. (1980, May).Three gentlemen, one ghost, and a skyscraper.Texas Monthly, 116-123, 242-263.

4. Adams, N. (2007).Skidmore, Owings and Merrill: SOM since 1936. Electa Architecture. 248-251.

5. Lemann, N. (1982, April).The architects.Texas Monthly, 143-151, 219-232.

6. Architectural Digest, 1972

7. Adams, 2007

8. (1968, February 15). Office tower design cuts framing costs. Engineering News Record, 41-42.

9. Khan, F.R., Stockbridge, G., & Brown, E.J. (1971).Quality control of high strength lightweight concrete for One Shell Plaza.ACI Special Publication, 29(2), 15-34.

10. Khan, F.R., 1971

11. Colaco, J.P. & Khan, F.R. Analysis and design of 715’ high concrete structure for One Shell Plaza.

12. Colaco & Khan